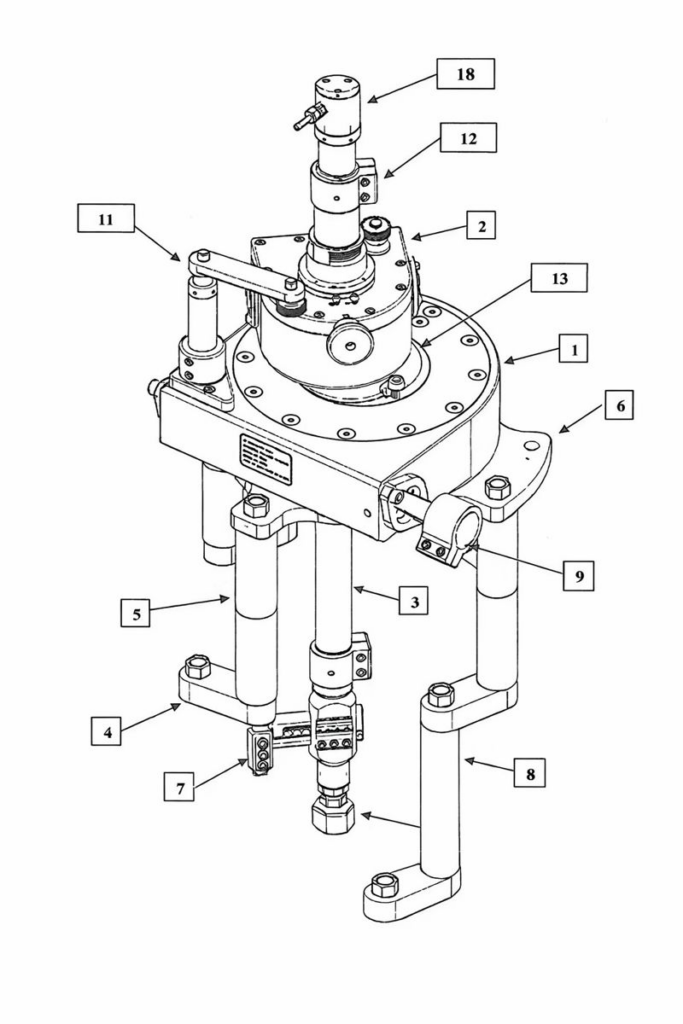

GGS-Valve Profiling Machine

The complete in-situ solution for Safety and Control Valve maintenance. Achieve surface flatness within 2 light bands in minutes. Cuts lapping time by 90% with diamond-coated technology.

The All-in-One Solution for Precision Valve Maintenance

Machine, grind, lap, and polish Safety and Control Valves to laboratory standards in a matter of minutes

Reduce service time by up to 90% while achieving surface textures < 3 microns

Stop Relying on Inefficient Manual Lapping

Manual lapping is time-consuming and prone to human error. It often leads to the seat face becoming “out of square” with the valve body, causing leaks and performance failures.

The GGS Advantage: Engineered for Accuracy

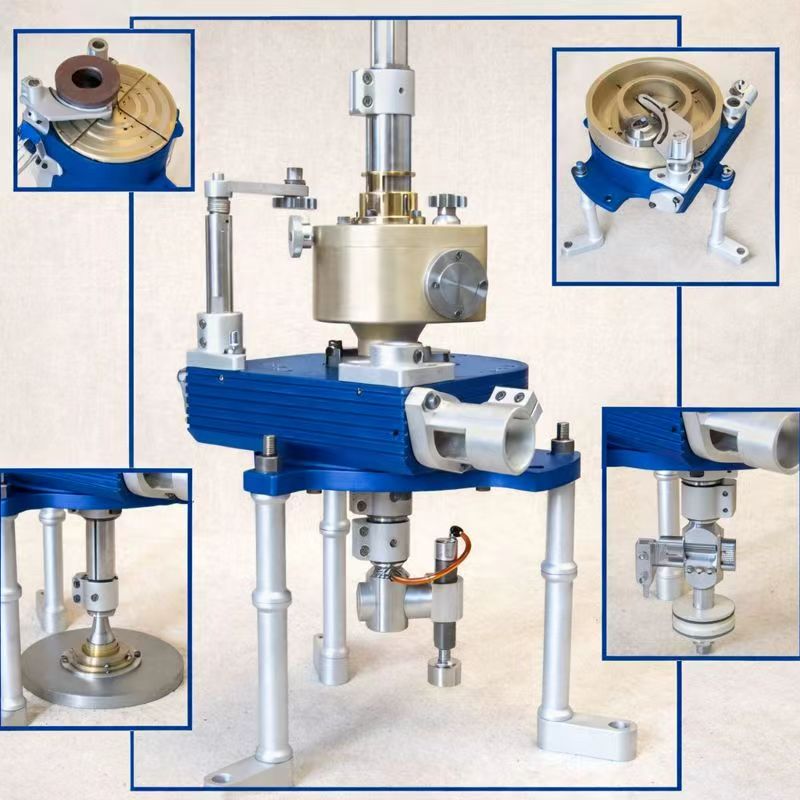

The GGS-Valve Profiling Machine (Model 03A) corrects these errors automatically.

Perfect Alignment: Maintains the seat perfectly square to the valve body.

Automatic Feed: Features a gear ratchet system that maintains a constant, automatic feed rate for the cutting tool, ensuring consistent results.

Visual Control: Designed for easy access and full visibility during the machining operation.

A Complete Restoration Cycle in Four Steps

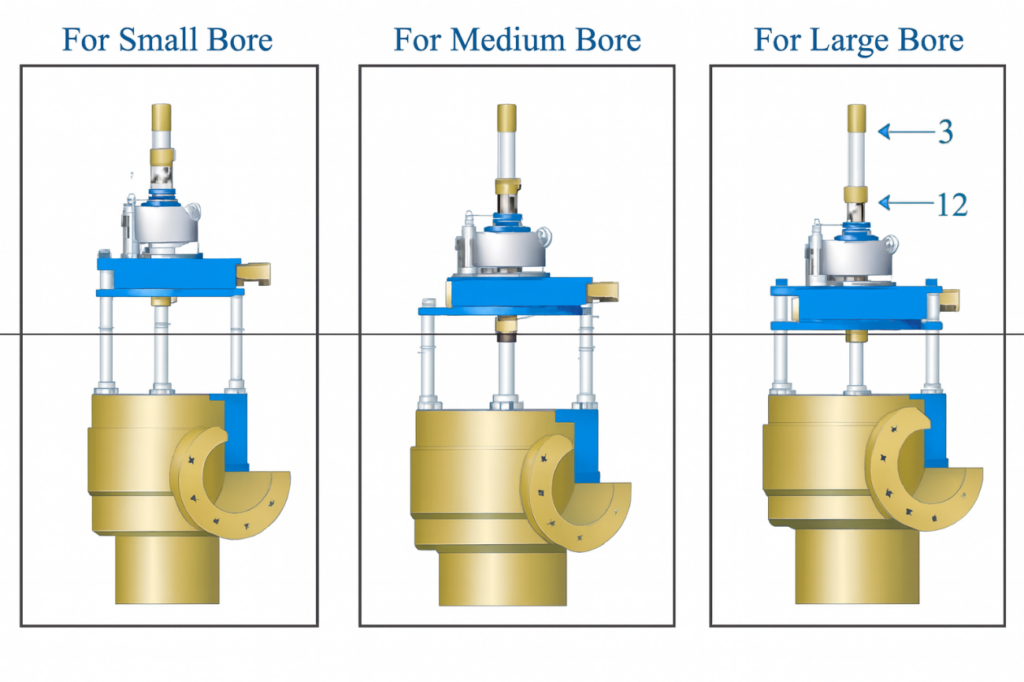

1. Heavy Duty Re-profiling

When the valve seat reaches its minimum critical dimension, re-profiling is essential. The GGS machine handles heavy machining of the seat profile using conventional cutting tools with ease.

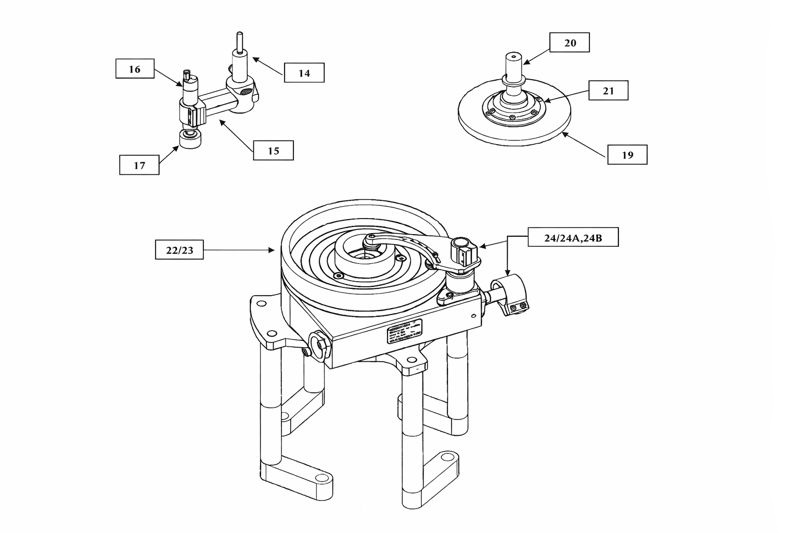

2. Rapid Material Removal (Grinding)

Utilizing diamond-coated grinding wheels rotating at 5,000 rpm, the machine rapidly removes material prior to lapping.

- Benefit: This process reduces overall lapping time by as much as 90%.

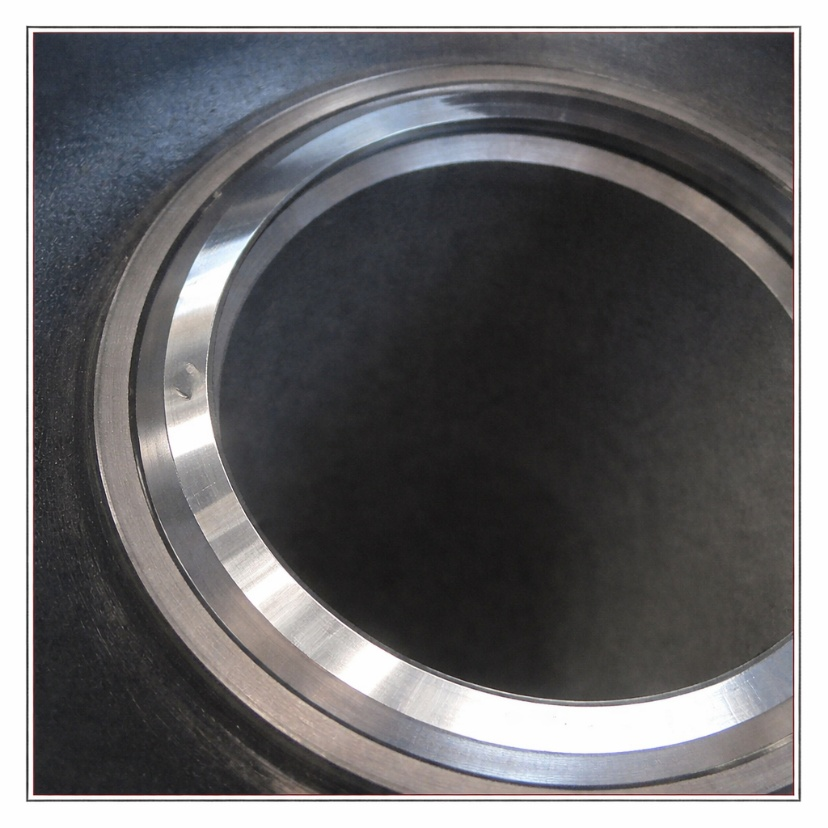

3. Precision Lapping & Polishing

Achieve equal lapping forces across the seat face via our specialized Swivel Joint technology.

- Random Motion: The lapping disc’s random motion ensures perfect flatness is transferred to the valve seat.

- Adjustable Action: An adjustable eccentric gearbox maximizes lapping action for speed and accuracy.

- The Result: A finished seat with surface texture within 3 microns and flatness within 2 light bands.

4. Valve Disc Maintenance

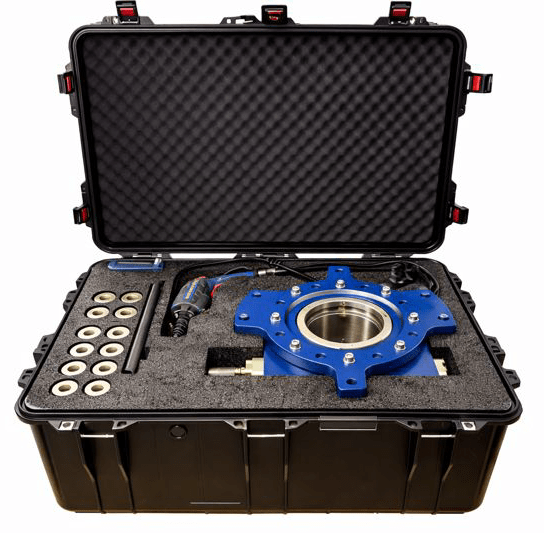

The system isn’t just for seats. Using the Lapping Ring Table Attachment, you can lap thermal discs with extreme accuracy. It delivers the same 3-micron/2-light-band precision for discs.

One System, Multiple Applications

- Complex Geometries: Capable of grinding new angles (e.g., 45-degree angles) on Control Valve seats.

- Tool Maintenance: Use the Merlin flat lapping table to recondition your Lapping Blocks, keeping them flat and in prime condition.

- Workshop Powerhouse (The Pedestal):

Transform the portable unit into a workshop station using the Merlin Pedestal. - Compatible with: Safety Valves, Control Valves, Globe Valves, and Gate Valves.

- Cost Savings: Performs machining, grinding, and lapping on valve bodies without the need for skilled lathe operators, significantly reducing labor costs.

Technical Data: Model 03A

| Feature | Specification |

| Main Drive | 110/240 3000 rpm 1/2” electric drill 700W |

| Optional Drives | Air Motor or Hydraulic Drive Motor |

| Grinding Motor | 2.9 kW |

| Diamond Wheels | Available in 80, 120, and 240 grit sizes |

| Machining Capacity | Min ID: ~5 cm |

| Eccentricity | Max 100mm |

| Portability | 3 Heavy-duty Cases (Total weight: 135 Kg) |

| Lapping Plates | Standard sizes: 100, 150, 200 mm (OD) |

Standard Lapping Ring Sizes (OD / ID):

- 300 / 270 mm

- 230 / 200 mm

- 165 / 135 mm

- 108 / 78 mm

- 75 / 45 mm

Trusted by Industry Leaders

Good Gear Solution Pte. Ltd. has spent decades researching and developing specialized maintenance equipment. We are a leader in the field of Safety Valve maintenance, backed by internationally recognized certifications:

- TUV SUD

- bizSAFE Level

- APF Spec Q Registered

- SAC Accredited Certification Body

Protected by Patents.

Ready to upgrade your maintenance capabilities?

Good Gear Solution Pte. Ltd. (Reg: 201820648N) Address: No.47J, Tuas South Ave 1, Tuas Cove Industrial Centre, Singapore 637247. Phone: +65 6592 0661 / +65 6592 0662 Email: info@goodgearsolution.com